Vertical Steel Structures

AT&V has been performing the engineering and construction for vertical steel structures associated with the storage of solids and liquids for over (30) years. Structures have been manufactured out of a variety of materials and have been shop fabricated, as well as field erected based on size. Some vertical towers are trayed or have internal baffle systems, while each of the solid storage structures may have altered design parameters based on the type of material, wall friction, bridging, and flow.

Structures designed and built by AT&V have been as large as 50’ in diameter and as tall as 250’. Projects have been constructed in the U.S. and overseas for a variety of industries. Some structures are designed to API, while most are designed to ASME. AT&V also supports the inclusion of the Steel Plate Fabricators Association’s guidelines associated with silos, bins, and hoppers.

For types of materials and/or thickness please refer to the AT&V Shop Fabricated document. In addition, this document reviews Quality Control Standards and other issues.

Solid Material Silos

Engineered, fabricated, and field erected by AT&V, this project refers to silos associated with the storage of a solid material that can polymerize when in contact with moisture. In addition, like many solids, there is the potential for particle suspension in air and explosion. Therefore, the design has magnetic doors to relieve explosive pressure, which can be tripped periodically to ensure they have not sealed shut from the product and potential moisture. The design also called for baghouse concepts to be incorporated by AT&V.

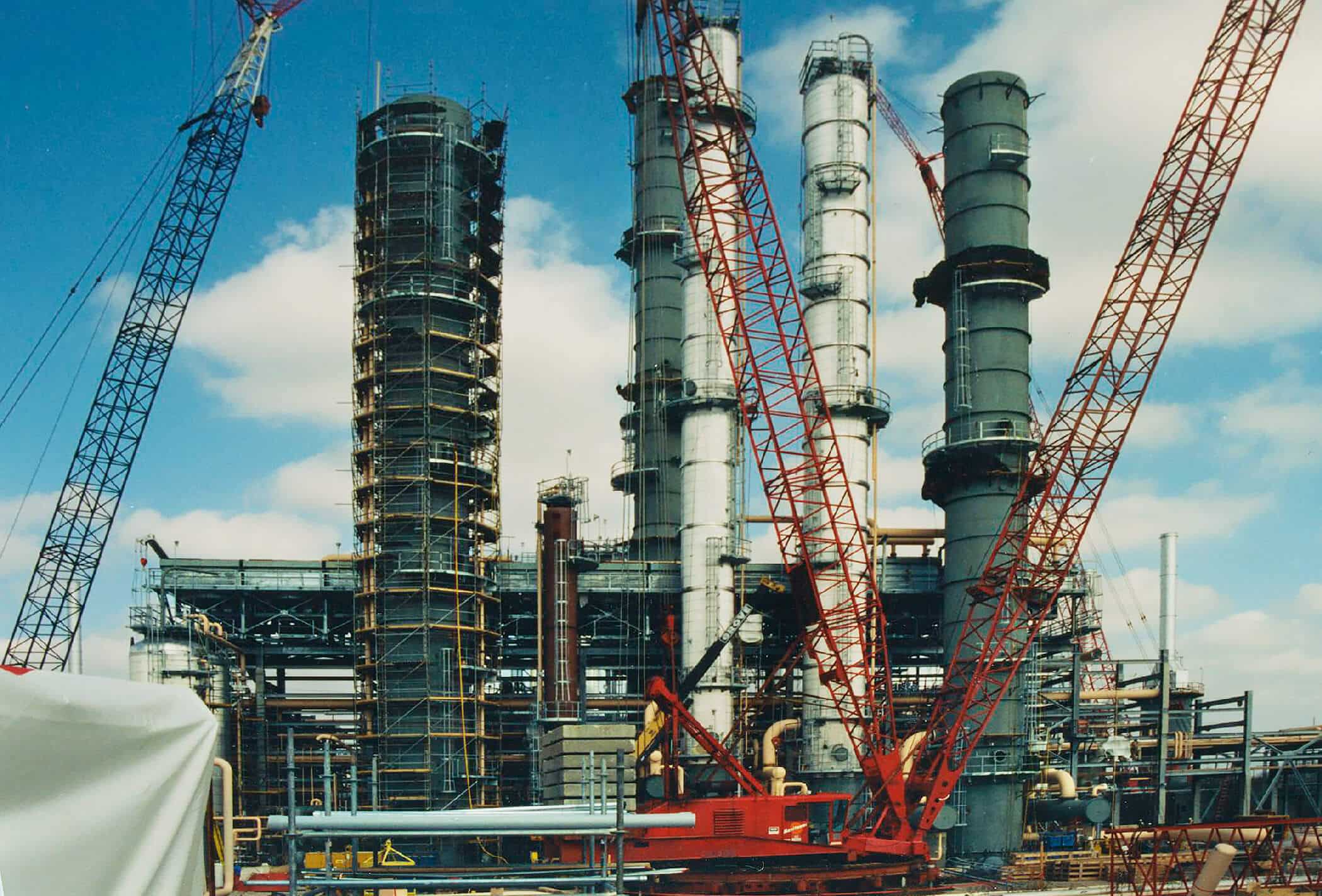

Tray Towers and Vertical Vessels

Engineered, fabricated, and field erected by AT&V, this project incorporates stamped ASME Section VIII, Div. 1 work, along with containment of pressure and internals for proper process support.

AT&V also installed trays and internal baffles to complete this project. AT&V fabricated the trayed towers and vertical vessels into segments at our shop and mobilized crews to set the segments together and finish welding, testing, etc.

Pelletized Steel Storage Silos with Rock Ladder

The project above required large silos for the storage of pelletized steel. The largest silo, measuring 50’ in diameter, required AT&V to design a rock ladder to minimize impact of falling materials on the structure, as well as degradation to the materials themselves. AT&V performed the engineering, fabrication, and field erection.

Vertical Vessels

This project represents vertical vessels holding liquid materials that suspend solids and require a variety of design cases to be considered. AT&V performed engineering, procurement, fabrication, as well as full field erection and testing of structures.

Continuous Digestor

The project above relates to a continuous digestor, similar to a coke drum, measuring 30’ in diameter and over 200’ tall. Some segments to the vessel were 5” thick for containing high pressure and liquid contents. This digestor is believed to be one of the largest in the world and has been in successful operation for several years. Heavy forming, welding, and testing were all performed within AT&V’s shops, supported by some of the heaviest forming equipment globally and the most advanced welding procedures and techniques.